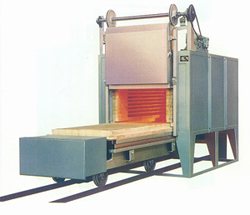

car bottom furnace

car bottom furnace applications: structure description: heating elements materials are the general international ocr27al7mo2 resistance wire, exclusively produced bending upwards of 20°-swap silk dormant silk brick, the maximum use temperature of 1440℃. taiwan cr-mn car equipped with nitrogen or 12℃ heat-resistant steel floor bearing silicon carbide furnace workpiece. furnace door movements through rolling round in the upper and lower guide rail rolling realized, ensuring that the closure furnace door at the furnace door furnace anastomosis between the seal, ensuring that the opening will not be in the process of friction injuring masonry. furnace door and the taiwan-car campaign is conducted by motor through worm reducer and the chain of transmission, and equipped with electricity magnetic brakes to make an appropriate adjustment. to improve temperature uniformity, high temperature bogie-hearth resistance furnace used bogie-type multi-zone heating and furnace door and after the wall layout heating components, high-power high temperature bogie-hearth resistance furnace multiple automatic temperature control counters were carried out on the multi-zone automatic temperature control heating and furnace door bogie operation. the control system of internation and temperature use the most advanced process technology curve in microcomputer automatic temperature control, ruling out manual error. according to the user needs heat treatment technology power curve automatically changes the size,outputing reasonable energy-saving power, making ideal curve achieves practical application of high-precision implementation in the heat treatment process . under the heat treatment process needs, arbitrary set each heating rate (that is, heating degree), each holding temperature (that is the need to start insulation), each holding time (that is, how long the need for the temperature insulation is).the process can be set ba duan curve. temperature is controled in precision of ±1℃ technical parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||